Extrusion is one of the basic steps in the production process for any material. It’s what gives a product its shape and form. In fact, extrusion is so important that it can be considered a manufacturing process in and of itself. If you don’t have an extruder gearbox in your workshop, you are limiting your potential and your business quite significantly. In this blog post, we will explore the importance of an extruder gearbox, and how it can help your business take on new challenges and grow faster than ever before.

What is an extruder gearbox

An extruder gearbox is a key component of 3D printing technology, and without it, printers would not be able to print objects with multiple colors or layers. An extruder gearbox is essentially a motor that rotates the print bed around the object being printed, and it does this by moving the hot filament through the head of the printer’s nozzle.

How does an extruder gearbox work?

An extruder gearbox is a key part of any 3D printer. It converts the movement of the print head, or nozzle, into rotational motion that can drive the printing material through the extrusion system.

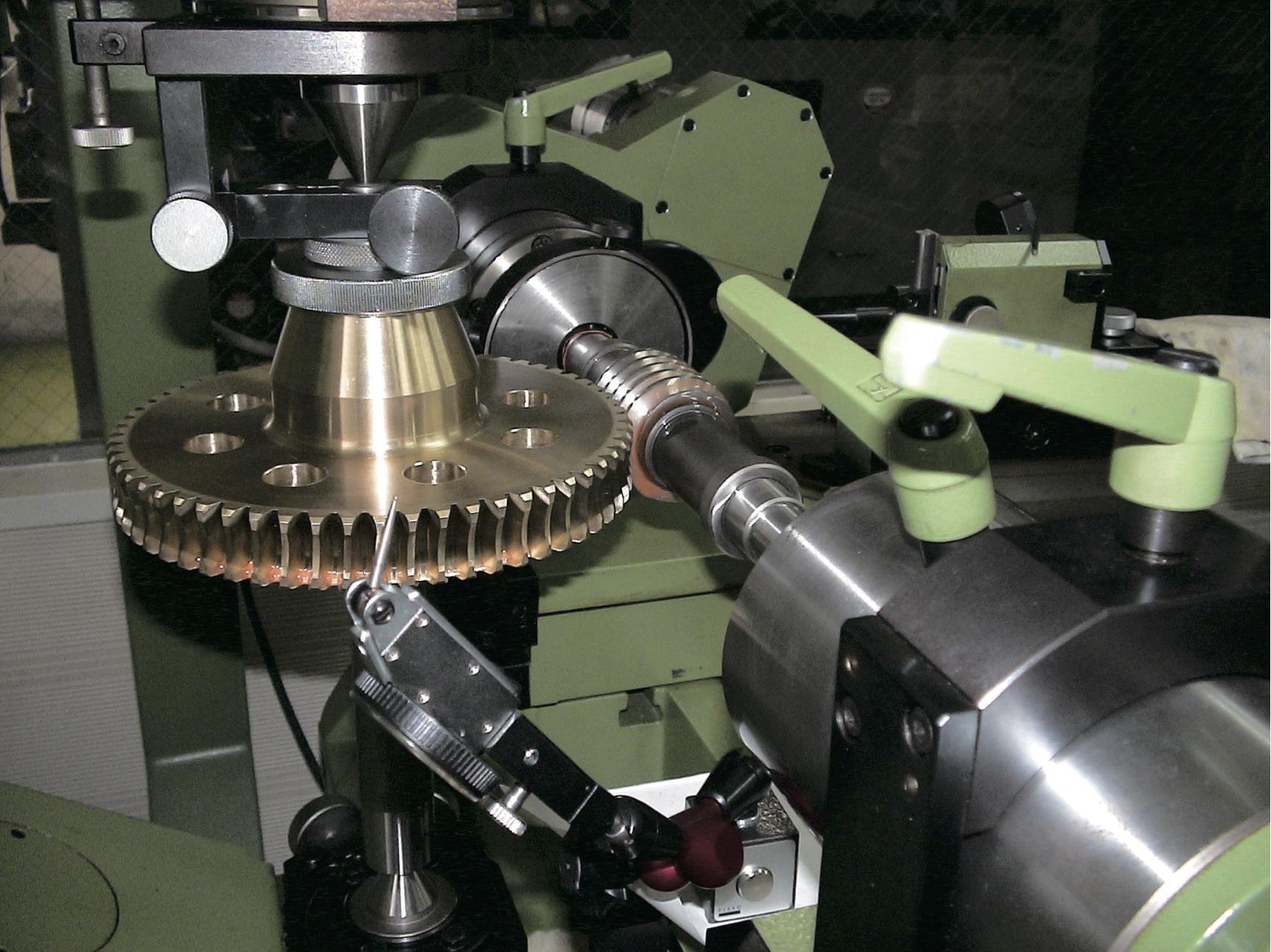

Extruder gears are typically made from hardened steel with precision machining capabilities and are often mounted on a metal shaft that connects to the main motor shaft. The gearbox continuously rotates the shaft and moves the print head in one direction or another.

There are two main types of extruder gearboxes: direct-drive and belt-drive. Direct-drive gearboxes use a geared arrangement to transfer power from the main motor shaft to the spindle, while belt-drive systems use a chain or serpentine belt to transmit power.

The various factors that affect printing performance, such as print speed, quality, and filament diameter, all rely on proper operation of an extruder gearbox. If it’s not functioning properly, your 3D printer will likely produce poor prints.

The Benefits of an Extruder Gearbox in Manufacturing

Manufacturing processes rely on machines to produce products. Extrusion is a manufacturing process that uses a nozzle to extrude melted plastic or other materials through a fine-mesh σ tube. The extruder gearbox helps to control the speed, temperature, and pressure of the molten plastic so that it can be formed into the desired shape.

One of the benefits of using an extruder gearbox is that it can help to improve production rates. The gearbox allows for consistent speeds throughout the machine, which can lead to increased efficiency and quality. Additionally, the gearbox helps to maintain temperature and pressure within the machine, which can result in improved product consistency and reduced processing time.

Overall, an extruder gearbox is essential for many manufacturing processes due to its ability to improve performance and accuracy.

Conclusion

If you’re in business, then you know that having the right extruder gearbox is essential for getting the most out of your 3D printing process. With so many 3D printing filaments on the market today, it’s important to have a machine that can handle any type of filament and print at the best possible speeds. If you’re not sure what an extruder gearbox is or what factors go into choosing one, read on to learn more about this important piece of equipment.