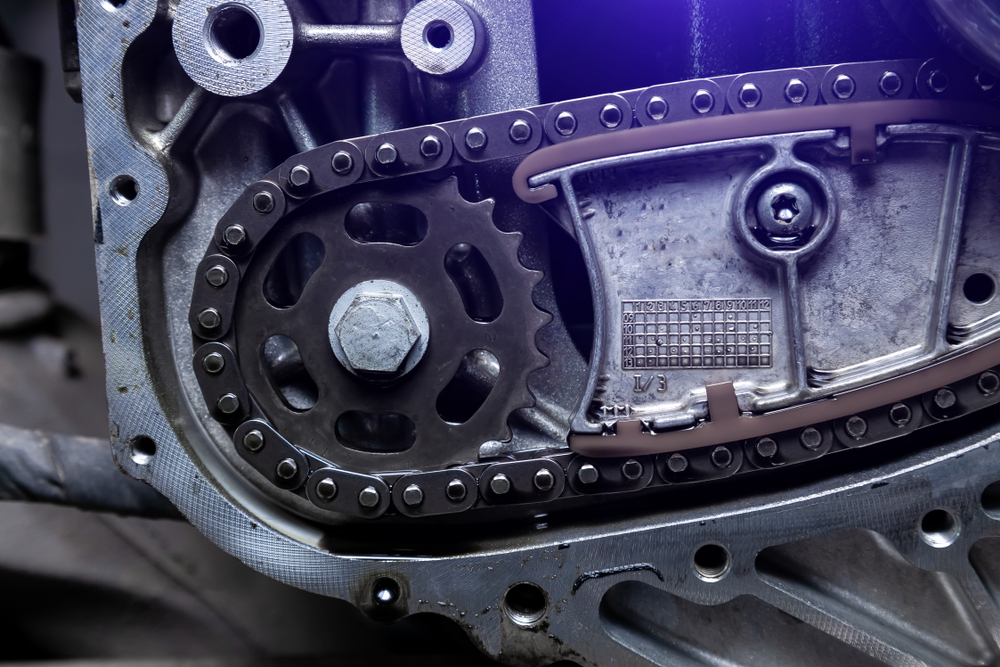

Roller chain sprockets are popularly referred to as single-strand sprockets. These are used largely for moving the conveyors. The string of teeth placed near the central bore is being used with roller chains to move the conveyors and machinery efficiently.

These sprockets are very economical and reliable systems, used widely in bicycles. Besides the same, they are also being used in different kinds of cars, machinery, conveyors, printing press and motorcycles. The roller chain sprockets have different kinds of capacities in terms of shock absorption.

You need to choose the best quality roller chain sprockets that are made of aluminium and coated with glass nylon. Nylon is a self-lubricating material that can make your sprockets rust-resistant and it also increases the durability level of the sprockets.

What are the five components of a standard roller chain sprocket?

Firstly, we need to know about the basic components of a roller chain sprocket before we discuss the maintenance of the same. The five major components of this are:

- Roller link plate

- Pink link plate

- Roller

- Bushing

- Pin

What are the major instructions that you should follow for maintaining a roller chain sprocket?

-

Knowing the procedure of installation

The friction between the bushing and pin is the major cause of chain lengthening. The roller chains are adequately pre-lubricated with oil to prevent rust development on the chain. Apart from that, most of the sprockets are designed with glass nylon, which is a self-lubricating material. You should always ensure that you do not wash the oil out.

Roller Chain Sprocket -

Knowing exacting when you should replace the roller chain

One should necessarily replace the roller chain when you start noticing any of the following issues:

- When you find a typical kind of crack visible on the surface of the link plate

- When the chain of the roller chain sprocket is seen to have uncertain movements

- When you find any nature of deformation on the pin

-

Thorough cleaning & lubrication

A roller chain sprocket drive should be well-protected from moisture and dirt. This is necessary to ensure that the chain is cleaned with kerosene oil & lubricated at frequent intervals. You shouldn’t use any heavy oil or grease as they are very stiff & can likely hamper the chain’s functioning. You should ensure that the oil surpasses the bearing area. So, you should necessarily apply the oil in between the link plates.

Schedule of maintenance and inspection of the roller chain sprockets

The periodic chain maintenance is very significant for obtaining ultimate vitality. If the roller chain sprocket is correctly installed, this can last longer than 15,000 hours.

The ideal maintenance schedule is as follows:

-

Routine inspection

- In this, you are required to check if the roller chain & the sprockets are properly attached.

- You should also check that the chain should not be very tight or loose.

- You should ideally check if there is a presence of dirt or dust or any other foreign body in the system that may likely hamper the smooth functioning of the roller chain sprocket

- You should check if the roller chain sprocket is adequately lubricated or not

- You should also check if any vibration or noise is produced when the chain is operating.

-

Day to day inspection

- Check if the roller chain is damaged

- Checked if the chain is dirty or rusted

- Checking if the chain is deformed or uneven

- Checking if the roller chain functions smoothly or not

- Checking whether there is any nature of the damage in the chains.

Conclusion

You should necessarily follow the above-discussed tips for the correct maintenance of the roller chain sprockets, which, in turn, will enhance its life considerably.